- C1/503-504 Celebration City Center, Gala gymkhana road, South Bopal Ahmedabad, Gujarat, INDIA

Reliable Forging and Precision-Forged Parts for Industrial Needs

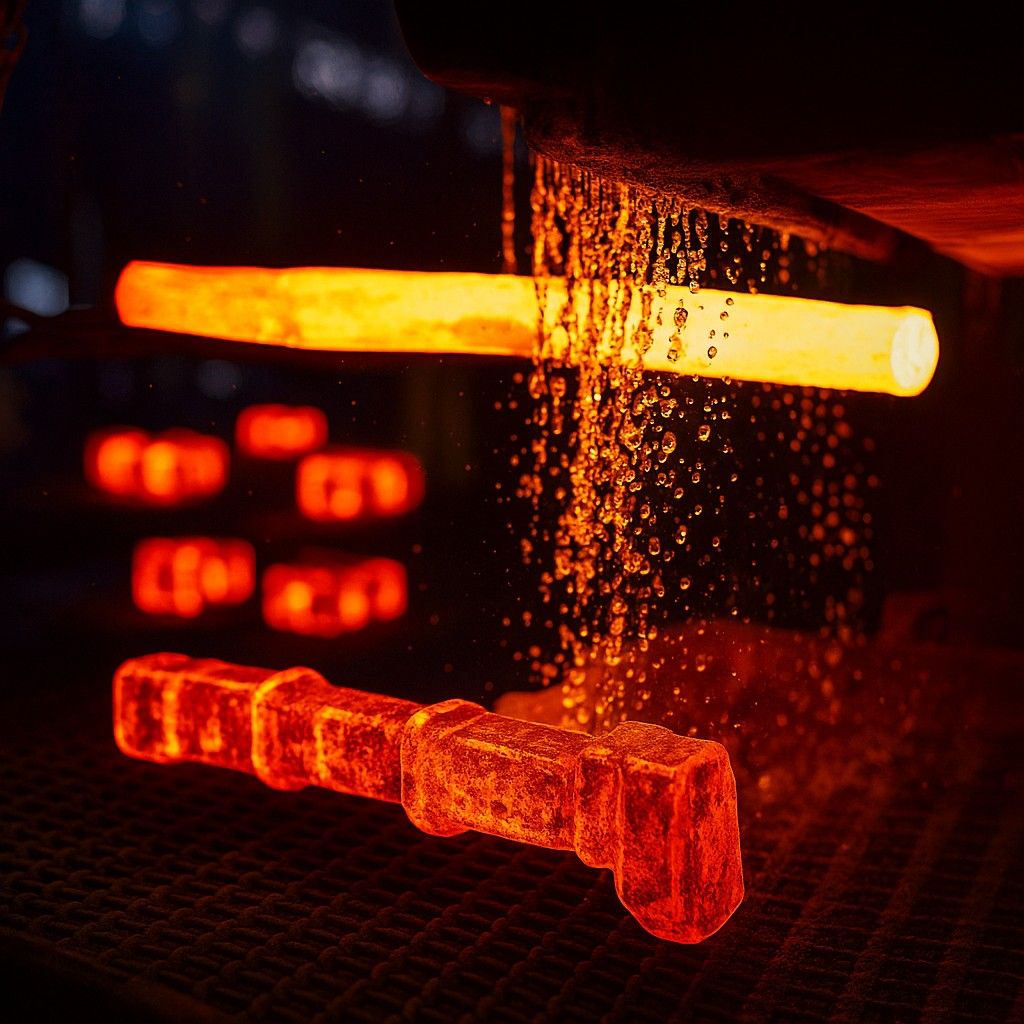

At Sharma Technocast, one of the best forging manufacturing companies in India, we combine engineering expertise with high-performance forging technology to produce precision-forged components for industries that demand strength, reliability, and durability. Based in Ahmedabad, India, we specialize in closed die forging, open die forging, and roll forging, serving sectors such as automotive, aerospace, heavy machinery, refinery, energy, and defense.

Our forged components are engineered to withstand tough operating conditions, resist fatigue, and deliver long-term performance in critical applications — from engine crankshafts and suspension parts to aerospace-grade forgings.

HEAVY-DUTY FORGING CAPABILITIES

Sharma Technocast’s forging infrastructure supports large-scale and high-strength applications across industries like construction, oil & gas, power generation, and railways.

Production range

100 kg to 10,000 kg forged components

Key equipment

10MT steam forging hammer, 1250-ton press forging machine, preheating and heat treatment furnaces

Capabilities

Complex geometries, large-size components, custom forging solutions

Our plant ensures structural integrity, superior grain flow, and metallurgical strength for every forged product.

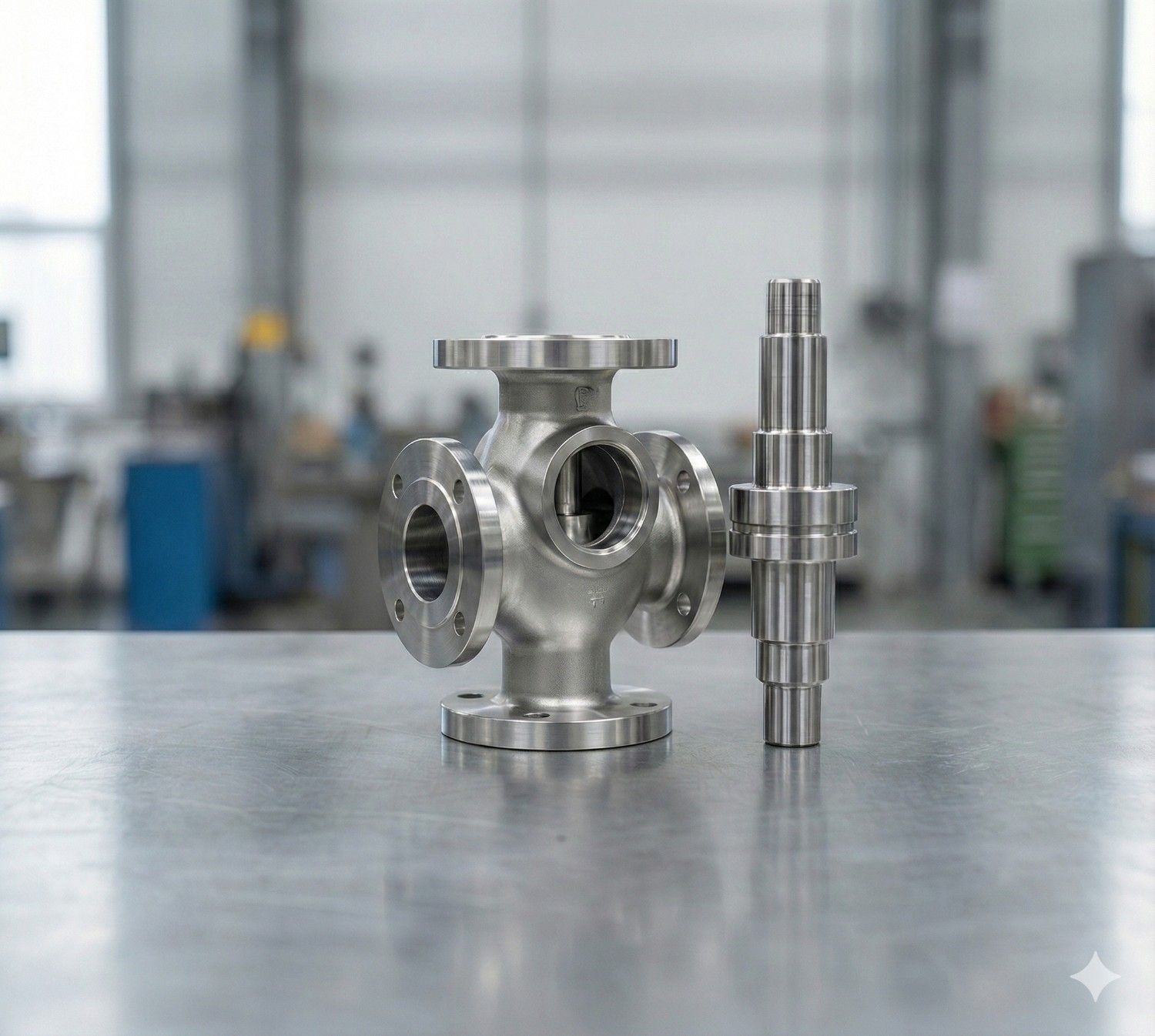

Precision Forging Facility

Our precision forging division delivers high-accuracy components with tight tolerances and superior surface finishes. Key capabilities include:

Equipped with CNC-controlled forging hammers, hydraulic press systems, and in-house die manufacturing units, we ensure repeatable precision, cost-effective production, and optimized material flow

Advanced Heat Treatment & Material Performance

We enhance the mechanical properties and durability of every forged component through precise heat treatment:

This ensures structural stability, wear resistance, and optimized performance in downstream CNC machining and industrial applications.

Materials We Forge

We work with a wide range of industrial-grade materials, including:

Our material selection ensures strength, fatigue resistance, and long-term reliability across automotive, aerospace, construction, and heavy engineering industries.

Quality & Testing

quality is integral to every forging process. Our rigorous testing and inspection include:

Our in-house annealing and normalizing furnaces deliver precise thermal treatment, ensuring mechanical properties meet or exceed industry standards.

Innovative Engineering Design Solutions

We deliver complete engineering support through:

Our team ensures design feasibility, performance optimization, and cost-effectiveness for every forged component.

Types of Forging

we offer a comprehensive range of industrial forging services designed to meet diverse application needs. Whether you require near-net shape forgings for the automotive sector or large open-die forged components for heavy engineering, we ensure precision, durability, and superior performance in every product.

Open Die Forging

Open die forging is a flexible and robust metal shaping process that transforms raw materials into precision-engineered components. Commonly used for large, custom shapes, this method enhances metal grain structure, improves mechanical properties, and ensures dimensional integrity. Ideal for low-volume production, aerospace applications, and heavy machinery components, open die forging offers superior strength and versatility.

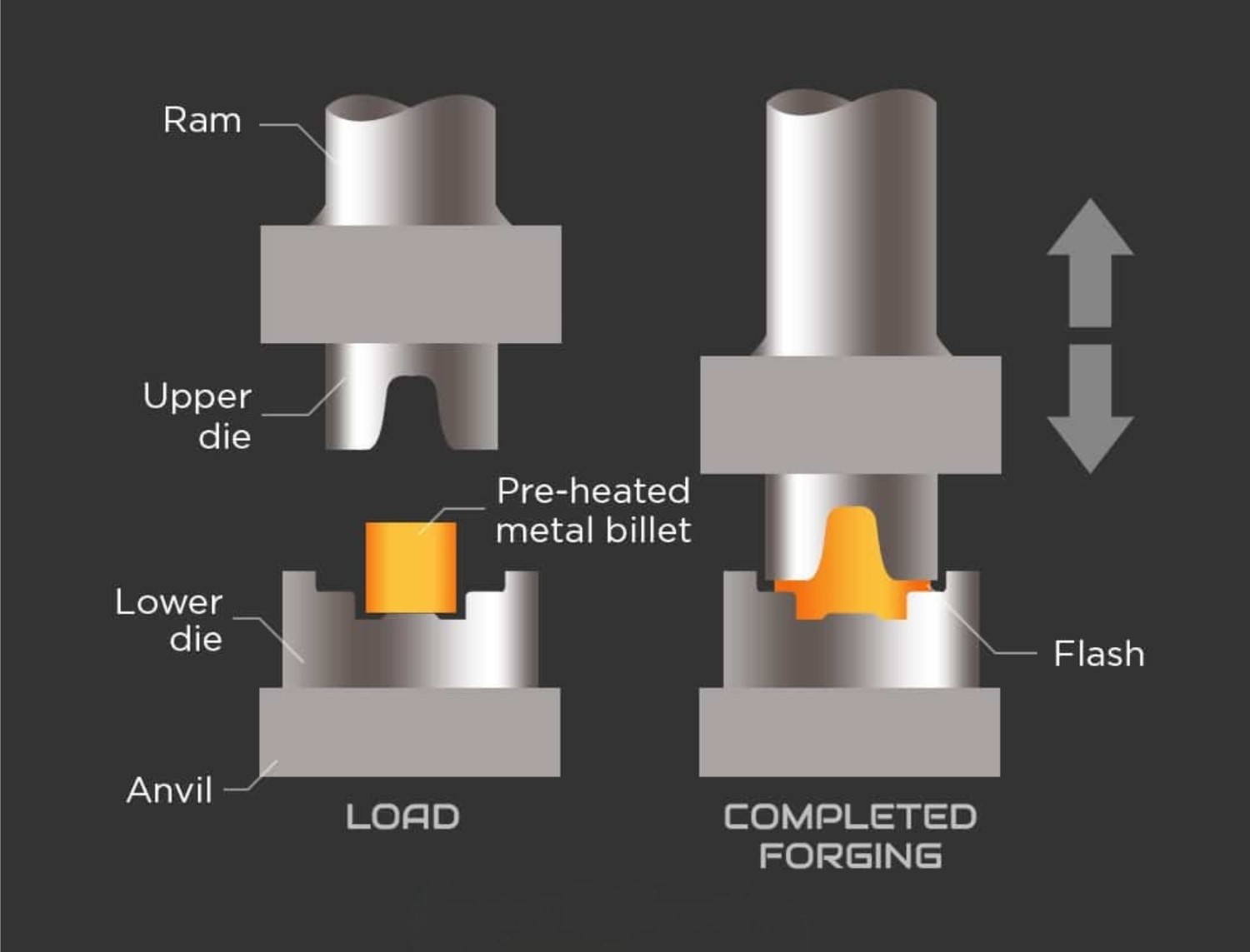

Closed Die Forging

Also known as impression-die forging, closed die forging is ideal for producing high-strength, high-precision components with complex geometries. Widely used in automotive, aerospace, and energy sectors, this method provides tight tolerances, improved grain flow, and repeatable near-net-shape production. It is the preferred solution for applications requiring maximum strength, accuracy, and reliability.

Roll Forging

Roll forging is a continuous forging process where metal billets are compressed between rotating rolls to create uniform and durable shapes. Perfect for shafts, tapered parts, and gear blanks, roll forging enhances metal strength, reduces material waste, and is highly suitable for high-volume production in railways, construction equipment, and automotive industries.

Material We Use

we work with a wide range of industrial-grade materials to meet diverse application requirements. Our forging capabilities include:

EN Series, AISI, LF, F-Series, SAE, IS Standards, Hot Die Steel

Custom profiles: round bars, flat bars, and unique geometries

These materials ensure mechanical strength, durability, and fatigue resistance, supporting industries such as automotive, aerospace, construction, and heavy engineering.

Proven Track Record

With 15+years of experience, Sharma Technocast has successfully delivered forged components to clients worldwide. Our projects reflect a commitment to innovation, quality, and practical engineering solutions, establishing us as a trusted forging manufacturer in Ahmedabad, India.

Testing & Quality Assurance

Quality is at the heart of our forging process. We perform rigorous testing to ensure each component meets industry and client standards.

- Ultrasonic Testing (Modsonic, Einstein II)

- Magnetic Particle Inspection (MPI)

- Digital Hardness Testing (Blue Star)

- Dye Penetrant (DP) Testing

- Impact Testing (Blue Star)

- Wet Lab

- UTE machine 40 tonnes (Blue Star)

- Gas Analyzer

- Microstructure Analysis,

- Spectro Analyzer

- Our annealing and normalizing furnaces deliver precise thermal treatment, and through quenching and tempering, we achieve the desired mechanical properties and material strength for all forged components.

Why Choose Sharma Technocast for Forging Solutions?

Sharma Technocast delivers high-strength forging solutions engineered for durability, dimensional accuracy, and long-term performance. Recognized as one of the best forging manufacturer company in Ahmedabad, India, we combine advanced forging technologies with strict quality control to produce reliable forged components. Our solutions are trusted by automotive, industrial, construction, and engineering industries across India and worldwide.

Request For Quote!

Ready to get started? Contact us today to discuss your project.

Our Experts Answers

Freqently Asked Questions

Forging is a manufacturing process where metal is shaped using compressive forces to improve strength, durability, and structural integrity.

Four types of forging manufacturing processes are commonly used to shape metal parts. These metal forging processes include Closed die forging , open die forging, cold forging, and roll forging.

The best forging method depends on part size, material, complexity, and strength requirements. For high precision and strength, closed-die forging is commonly preferred.

Forging materials include carbon steel, alloy steel, stainless steel, aluminum, brass, copper, and high-strength alloys, selected based on application needs.

- Casting: Metal is melted and poured into a mold.

- Forging: Solid metal is compressed and shaped under force.

Forged parts typically offer higher strength, toughness, and reliability.

Read More...

- Hot forging: Done at high temperatures for better ductility and complex shapes.

- Cold forging: Done at room temperature for better surface finish and dimensional accuracy.

Sharma Technocast provides open-die, closed-die, hot forging, cold forging, roll forging and precision metal forging solutions for automotive, machinery, construction, and industrial applications with worldwide delivery.

Read our full forging solutions: https://www.sharmatechnocast.com/forging/