-

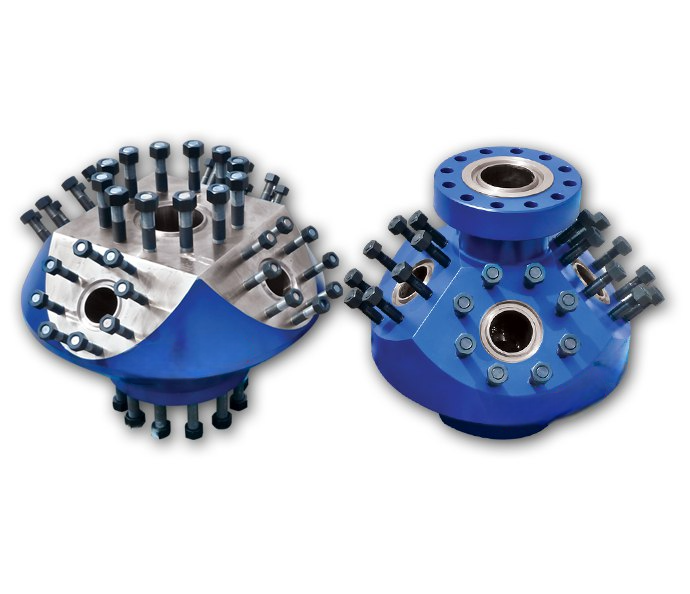

Component with studded connections on each end, used to connect flanges with different nominal sizes, pressure ratings and configurations.A Double Studded Adapter (DSA) is commonly used to connect flanges with different nominal sizes, pressure ratings, and configurations. *Various sizes and pressure ratings, custom manufacturing available.

-

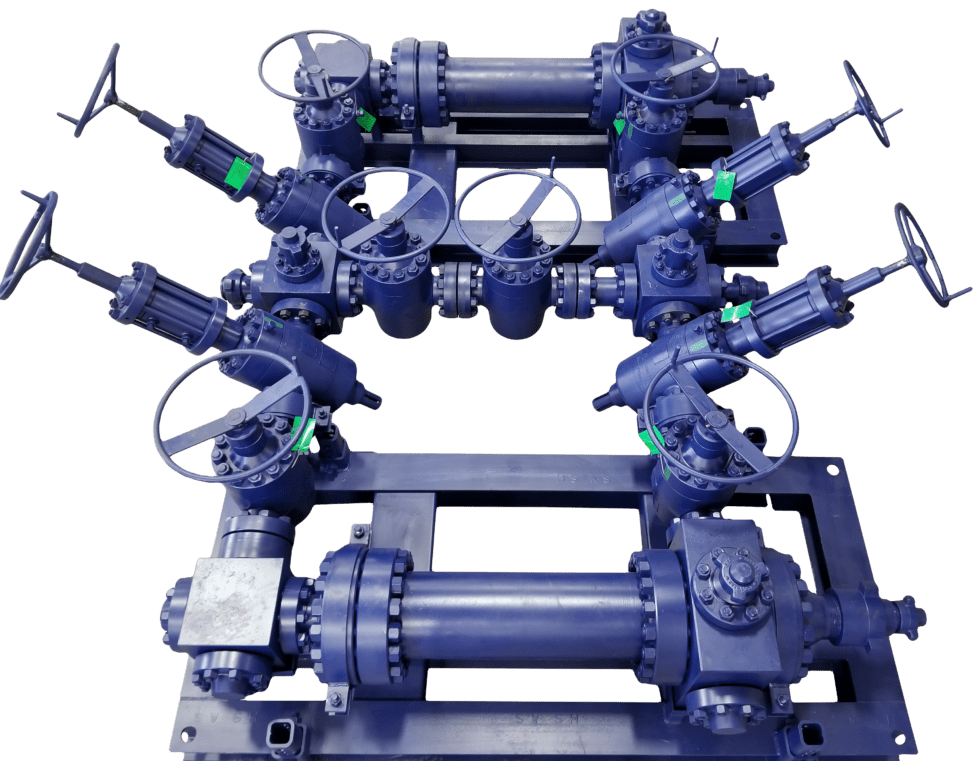

Equipment with flanged ends of equal size used to separate two components by a determined length with outlet connections to allow access.Drilling spools usually have the same nominal end connections and the same nominal outlet connections. Usually made to any combination of end connections and outlet connections as well as overall height or length (OAL) and outlet extension. *Various sizes and pressure ratings, custom manufacturing available.

-

TYA offers frac stacks and components in all various sizes and pressure ratings. Custom manufacturing available. Various sizes and pressure ratings, custom manufacturing available.

-

The Gate Valve is designed to meet the high demands of current fracking technology. Custom sizes and pressures available.

-

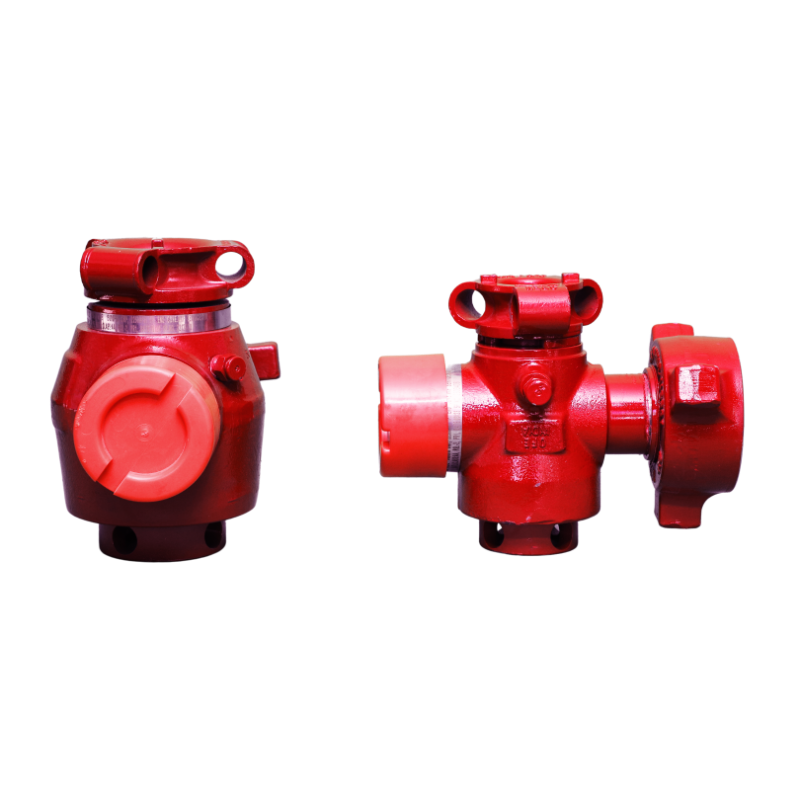

Component that allows multiple flow lines to be compiled into one bore generally used on frac tree and manifolds during fracturing.Goat head frac adaptor is the equipment often used on frac tree and frac stack during fracturing work, which is often in studded and flange-end connections, which is often in studded and flange-end connections. Features:

- Available in sizes from 4 1/16″ thru 7 1/16″. Working pressures of 10,000 and 15,000.

- Facet configuration of 4 or 6 outlets.

-

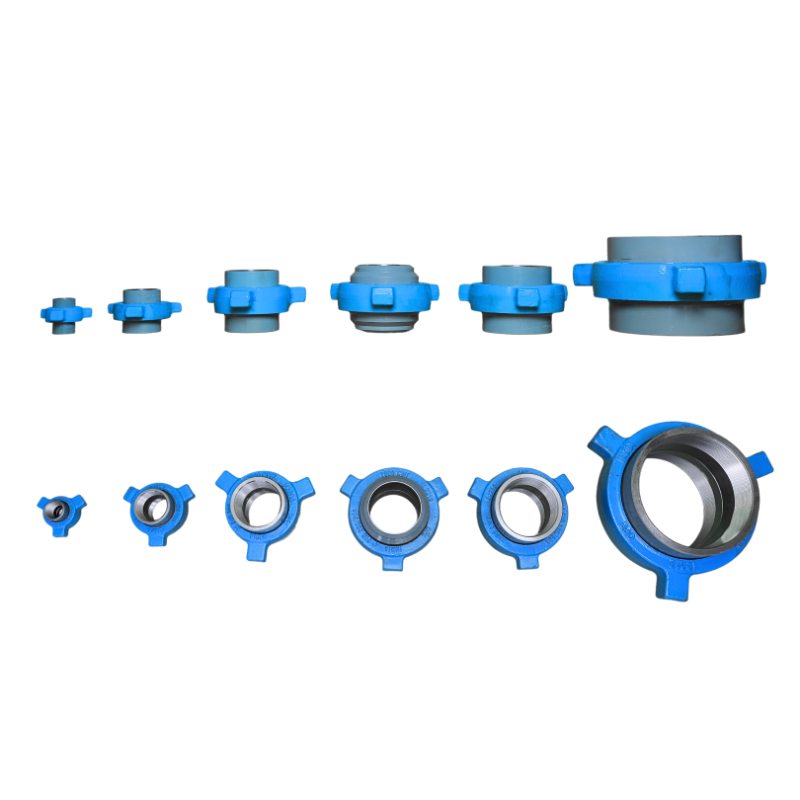

Hammer Unions & Hose Union Fittings – TYA

TYA offers a complete range of OFC/OFE hammer unions designed for durability, reliability, and high performance in demanding applications. Available in sizes up to 15,000 psi working pressure, our hammer unions are offered in pressure seal, non-pressure seal, and welded styles to suit diverse operational needs.

All OFE hammer unions deliver pressure-tight, positive sealing and are available in both standard service and sour gas models. For sour gas applications, our hammer unions undergo special heat treatment for controlled hardness and incorporate fluorocarbon elastomer seal rings for superior sealing performance and enhanced safety.

Specifications for Threaded & Butt Weld Hammer Unions ensure compatibility, strength, and longevity in critical environments.

Our OFC/OFE Figure 206 Hose Union Fittings, crafted from high-quality cast ductile iron, provide a versatile solution for hose connections. Also known as Hose Barb Unions, they feature a union end connection compatible with Figure 200/206 and include an integral hose shank on both male and female subs.

The Figure 206 design eliminates the need for welding a hose nipple onto a hammer union, offering significant time and cost savings. Each unit is tested to twice the rated working pressure, meeting the rigorous demands of TYA’s high-performance hose applications.

Key Advantages:

-

High-pressure capacity up to 15,000 psi

-

Available in multiple connection types and sizes

-

Specially treated for sour gas service durability

-

Precision engineering for positive, leak-free sealing

-

Time-saving, weld-free hose connection design

-

Exceeds standard pressure testing requirements

TYA’s hammer unions and hose fittings are engineered to deliver maximum safety, reliability, and efficiency in oilfield, industrial, and heavy-duty operations.

-

-

Integral Union Connections & Accessories – TYA

At TYA, we supply high-pressure integral union connections (OFC/OFE) engineered for exceptional durability and performance. Available in 2" and 3" sizes with pressure ratings up to 15,000 psi NSCWP (Non-Shock Cold Working Pressure), our high-strength alloy steel unions feature a lightweight design for easier handling without compromising safety. Each integral union connection undergoes a controlled heat-treat process for maximum strength and reliability in oilfield and industrial applications.

Union Changeover & Crossover Adaptors

TYA offers union changeover adaptors and union crossover adaptors in female-to-male, female-to-female, and male-to-male configurations from 1″ to 4″. Designed for standard service up to 15,000 psi and sour gas service up to 10,000 psi, these high-pressure adaptors ensure secure, leak-free, and compatible connections across multiple thread types.

Union Bull, Gauge & Lifting Bull Plugs

Our union bull plugs, gauge plugs, and lifting bull plugs are available in multiple sizes and thread types, delivering pressure ratings up to 15,000 psi NSCWP for standard service and 10,000 psi for sour gas service. Built from premium alloy steel, these plugs provide dependable sealing and long-term durability in harsh environments.

Union Male & Female to Pipe & Tubing Thread Swages

TYA’s union-to-pipe thread swages and union-to-tubing thread swages come in 1″ to 4″ sizes, with pressure ratings from 6,000 psi to 10,000 psi. Engineered for high-pressure connections, these swages deliver secure, leak-proof performance in oilfield, industrial, and heavy-duty applications. -

TYA plug catchers and components in all various sizes and pressure ratings. Custom manufacturing is available.Bestway plug catchers support well cleanup by filtering isolation plug remnants and fragments of casing, cement, and loose rock from the perforation area. Catchers feature a single barrel with bypass or dual barrels (for continuous filtration during blowdown activities). Our 10,000-psi to 15,000-psi working pressure catchers remove large solid debris immediately after the fracturing stack.

- Single barrel with bypass or dual barrel

- 10,000-psi to 15,000-psi working pressure

- Critical service rated

- Plug valve or gate valve-based design

- Availability of hydraulically controlled dumping option

-

Plug Valves – TYA

TYA manufactures high-performance plug valves designed for reliable control in demanding high-pressure oilfield and industrial applications. Available in Standard Service and H₂S Service configurations, our plug valves meet rigorous industry standards with:

-

Standard service: up to 15,000 psi working pressure, 22,500 psi test pressure

-

H₂S service: up to 10,000 psi working pressure, 15,000 psi test pressure

Constructed with a rugged forged alloy steel body, these valves ensure strength, durability, and long service life even under extreme conditions.

Design & Features

-

Bottom entry and top entry designs for easy maintenance

-

Interchangeable valve parts with most major industry designs

-

Serialized for full traceability

-

MTR (Material Test Report) and Pressure Test Report available on request

-

Suitable for fracturing, cementing, acidizing, and other high-pressure operations

Plug Valve Assembly Components

Each plug valve assembly includes:

-

Cap Screw (2 pcs)

-

Washer (Small) – 2 pcs

-

Washer (Bigger) – 2 pcs

-

Handle Adapter – 1 pc

-

Stop Bolt – 1 pc

-

Stop Collar – 1 pc

-

Grease Fitting – 1 pc

-

Body – 1 pc

-

Wing Nut – 1 pc

-

Segment – 3 pcs

-

Retainer Ring – 1 pc

-

Lip Seal – 2 pcs

-

Plug Seal – 2 pcs

-

Plug – 1 pc

-

Roll Pin – 1 pc

-

Insert – 2 pcs

-

Insert O-ring – 2 pcs

-

Adjusting Nut O-ring – 1 pc

-

Adjusting Nut – 1 pc

Plug Valve Repair Kit

The repair kit set includes:

-

Plug Seal (2 pcs)

-

Plug (1 pc)

-

Insert (2 pcs)

-

Insert O-ring (2 pcs)

-

Adjusting Nut O-ring (1 pc)

Available Sizes & Specifications

Size End Connection Service Working Pressure Test Pressure Operation Type A (in) B (in) C (in) D (in) E (in) 1502 MxF Standard 15,000 22,500 Handle 10.53 4.74 4.50 4.50 1.00 1502 MxF H₂S 10,000 15,000 Handle 10.53 4.74 4.50 4.50 1.00 LP Thread Standard 10,000 15,000 Handle 8.50 5.41 5.25 6.85 2.05 1502 MxF Standard 15,000 22,500 Handle 13.88 5.41 5.26 6.85 1.75 1502 MxF H₂S 10,000 15,000 Handle 13.88 5.41 5.26 6.85 1.75 1502 MxF Standard 15,000 22,500 Gear 17.00 7.20 9.06 3.05 3.05 1502 MxF H₂S 10,000 15,000 Handle 17.00 7.20 9.06 3.05 3.05 Custom sizes available on request.

Key Advantages

-

High-pressure capacity: up to 15,000 psi

-

Forged alloy steel body for durability

-

Interchangeable parts reduce downtime and costs

-

Easy maintenance design (bottom/top entry)

-

Wide application range in oilfield & industrial operations

-

Complete repair kits for extended service life

-