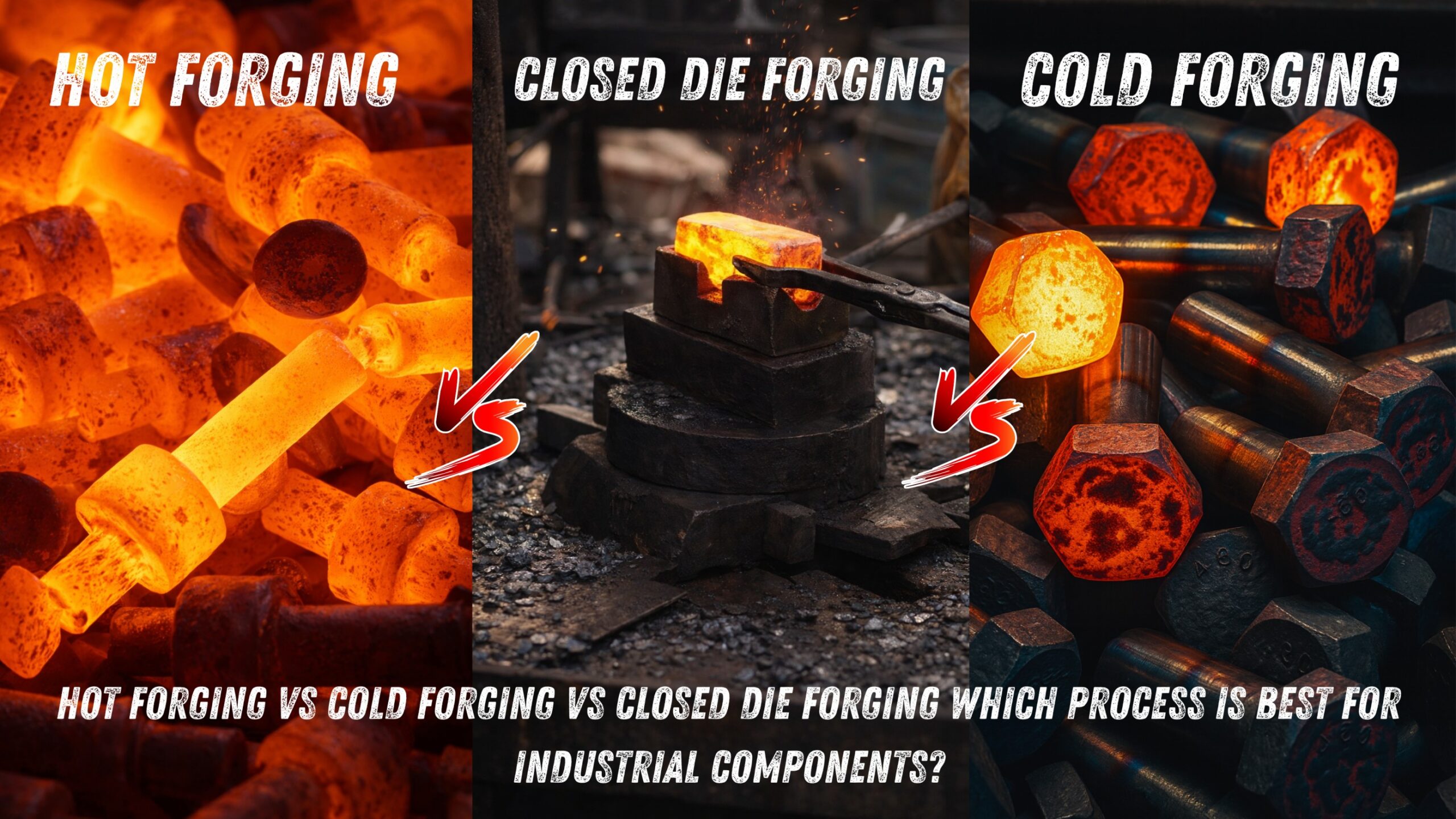

Hot Forging vs Cold Forging vs Closed Die Forging

Forging is one of the most critical manufacturing processes used to produce high-strength, durable, and reliable industrial components. In industries such as automotive, machinery, oil & gas, construction, power generation, and heavy engineering, the choice of forging process directly impacts component performance, cost, and longevity.

At Sharma Technocast, a trusted forging components manufacturer in Ahmedabad, India, we specialize in delivering high-precision forged components using advanced forging techniques. In this blog, we explain the differences between Hot Forging, Cold Forging, and Closed Die Forging, and help you understand which process is best for your industrial requirements.

What Is Forging?

Forging is a manufacturing process in which metal is shaped using compressive forces, usually delivered by a hammer, press, or die. Unlike casting, forging improves the internal grain structure of the metal, resulting in higher strength, better fatigue resistance, and superior mechanical properties.

Forged components are widely used for critical industrial applications where performance and safety are essential.

Hot Forging

What Is Hot Forging?

Hot forging is performed at temperatures above the metal’s recrystallization point. Heating the metal makes it easier to shape, allowing complex geometries and large components to be manufactured efficiently.

Advantages of Hot Forging:

Excellent strength and toughness

Improved grain flow

Suitable for large and complex components

Reduced risk of cracking during deformation

Applications:

Automotive components

Heavy machinery parts

Construction equipment

Oil & gas and refinery components

Industrial shafts and flanges

Hot forging is ideal when durability and mechanical performance are the top priorities.

Cold Forging

What Is Cold Forging?

Cold forging is performed at or near room temperature. This process is commonly used for producing small, high-volume components with tight dimensional accuracy.

Advantages of Cold Forging:

High dimensional accuracy

Excellent surface finish

Reduced material waste

No heating cost

Applications:

Fasteners

Small precision components

Automotive fittings

Electrical and hardware parts

Cold forging is best suited for mass production of smaller components where precision and surface quality are critical.

Closed Die Forging

What Is Closed Die Forging?

Closed die forging (also known as impression die forging) uses shaped dies to form the metal into precise dimensions. This process can be performed hot or warm, depending on the application.

Advantages of Closed Die Forging:

Near-net shape production

High strength and consistency

Excellent dimensional control

Suitable for complex geometries

Applications:

Forged automotive parts

Industrial components

Heavy-duty engineering parts

Custom forged components

Closed die forging is the preferred choice for high-performance industrial components that require accuracy and reliability.

Which Forging Process Is Best for Industrial Components?

The best forging process depends on:

Component size and complexity

Mechanical strength requirements

Production volume

Industry application

Cost considerations

For heavy-duty industrial components, hot forging and closed die forging are usually the best options. For small, high-volume precision parts, cold forging is more suitable.

At Sharma Technocast, our engineering team evaluates your application requirements and recommends the most efficient forging solution for optimal performance and cost efficiency.

Why Choose Sharma Technocast for Forging Components?

Sharma Technocast is a leading forging manufacturer in India, offering:

Hot forging services

Closed die forging solutions

Custom forged components

High-precision engineering support

Strict quality control and testing

Along with forging, we also provide:

FAQs:-

Q1. What is the best forging process for industrial components?

Hot forging and closed die forging are best for industrial components due to their strength and durability.Q2. What industries use forged components?

Automotive, machinery, oil & gas, refineries, construction, power plants, and heavy engineering industries widely use forged components.Q3. Is closed-die forging better than open die forging?

Closed die forging offers better dimensional accuracy and consistency for complex components.Q4. Who is a reliable forging manufacturer in India?

Sharma Technocast is a trusted forging manufacturer in Ahmedabad, India, delivering high-quality industrial forging solutions.