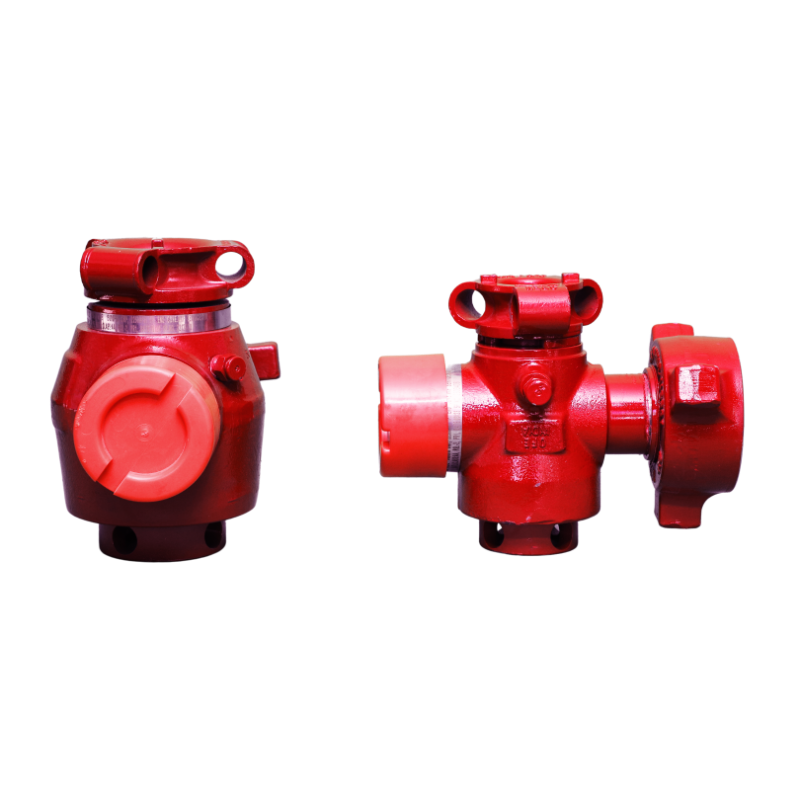

TYA Valve

The TYA Frac Valve is designed to meet the high demands of current fracking technology. Custom sizes and pressures are available.

Available in multiple configurations

- TYA Hydraulic Frac Valve

- TYA Manual Frac Valve

- All Sizes

- All Pressures

- Custom Frac Valves