-

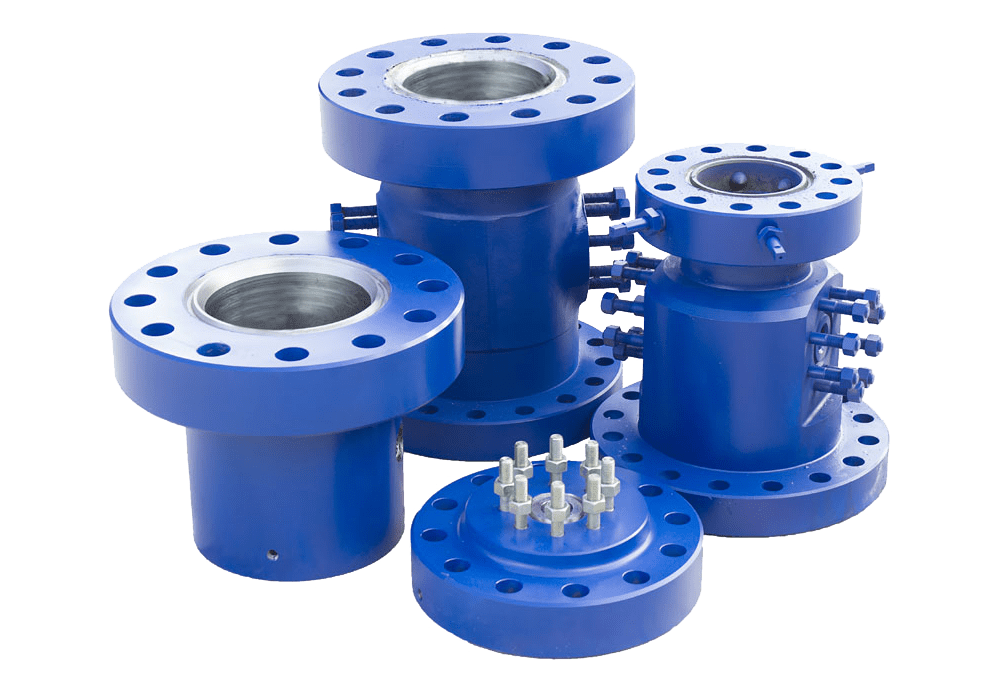

Tya Adapter Spools are available with flanged ends of various sizes. An adapter spool separates two components by a determined length with different end connections.Adapter spools are used to connect drill-through equipment with different end connections, nominal size designation and/or pressure ratings to each other. *Offering the best adapter spool in the industry today. Multiple sizes and pressures; custom manufacturing available. For more information, contact us today.

-

TYA API 6A Ring Gaskets – Precision Sealing for High-Pressure Applications

TYA API 6A Ring Gaskets are engineered to deliver reliable, leak-proof sealing in high-pressure and high-temperature environments commonly found in oilfield, petrochemical, and industrial applications. Manufactured to API 6A specifications, these gaskets ensure precision finish, superior durability, and compliance with the most stringent industry standards.

Key Features:

-

Material Options: Available in Stainless Steel, Low Carbon Steel, or Inconel for optimum performance in various service conditions, including corrosive and sour gas environments.

-

Dual Certification for Low Carbon: Meets the requirements for low carbon content materials, enhancing weldability and preventing corrosion in service.

-

Precision Finish: Machined to exact tolerances for a perfect metal-to-metal seal, ensuring optimal sealing performance under extreme pressures.

-

Full Traceability: Each gasket is serialized and fully traceable to its raw material source, with complete MTR (Material Test Report) documentation available.

-

API Compliance: Designed and tested in accordance with API 6A standards for ring joint gaskets, ensuring compatibility with all standard API flanges and wellhead equipment.

Benefits:

-

Exceptional sealing integrity for both high-pressure and high-temperature service.

-

Corrosion and wear resistance for extended service life.

-

Compatible with standard API BX, R, and RX profiles.

-

Ideal for wellhead, valve, and high-pressure piping systems.

-

-

Blind Flanges are a solid flange with relevant bolt holes used to blank off an opening. Test Flanges are a solid flange with relevant bolt holes with a port to monitor pressure, used to blank off an opening.Blind flanges are used to seal the end of high pressure openings. They are commonly used for capping the flow of gas or liquid through a combination of oil and gas products. Blind flanges also allow for easy access to the equipment in case work must be done inside the flow. They are oftentimes used for high pressure applications. Test flanges are commonly known for their 9/16th UNF and ½ inch NPT. While a Blind Flange will commonly not have any holes. *Offered in multiple sizes and pressures

-

Various sizes and pressure ratings, custom manufacturing available.Casing Heads, Tubing Heads, Casing Spools

-

TYA Choke & Plug Valve Product Range

Choke Overview

-

Sizes: 2" Fig 1502 MxF with 3/4" or 1" Orifice, 3" Fig 1502 MxF with 2" Orifice

-

Service Ratings:

-

Standard Service: Up to 15,000 psi, Tested at 22,500 psi

-

H₂S Service: Up to 10,000 psi, Tested at 15,000 psi

-

-

End Connection: Hammer Union

-

Material: Forged Alloy Steel Body, Stainless Steel & Tungsten Carbide Parts

-

Compatibility: Interchangeable with major brands

-

Applications: Wellheads, Well Testing, Steam Injection, Choke & Kill Manifolds, Well Clean Operations

2" Positive Choke Valve

Features:

-

Body-to-bonnet contact behind O-ring prevents seal extrusion

-

Choke beans made of Ceramic or Hard Alloy Steel

-

Flow Bean Chamfers: 2/64" to 64/64" in 1/64" increments

-

Quick choke bean change without full disassembly

Specifications:

-

Design & Test: API 6A

-

Pressure Ratings: 2000–20000 psi

-

Sizes: 1-13/16" to 4-1/16"

-

PSL Levels: PSL1–PSL4

-

PR Levels: PR1, PR2

-

Material Classes: AA–FF

-

End Connections: Flanged, Threaded, Flanged & Threaded

Repair Kit Includes: Choke Bean (Qty: 1)

2" Adjustable Choke Valve

Features:

-

Long life, low maintenance

-

Locking stem device

-

Convertible to Positive Choke

-

High-strength alloy steel stem

-

Abrasion & erosion resistant

-

Easy seat & valve removal without special tools

Repair Kit Includes:

-

Stem Guide (x2)

-

Stem Seal (x2)

-

Junk Ring (x1)

-

Snap Ring (x1)

3" Adjustable Choke Valve

Repair Kit Includes:

-

Outsider O-ring (x2)

-

Seal Piston (x1)

-

Inside O-ring (x2)

-

Stem Seal (x1)

-

Snap Ring (x2)

-

Bonnet O-ring (x1)

-

Bonnet Back-Up Ring (x1)

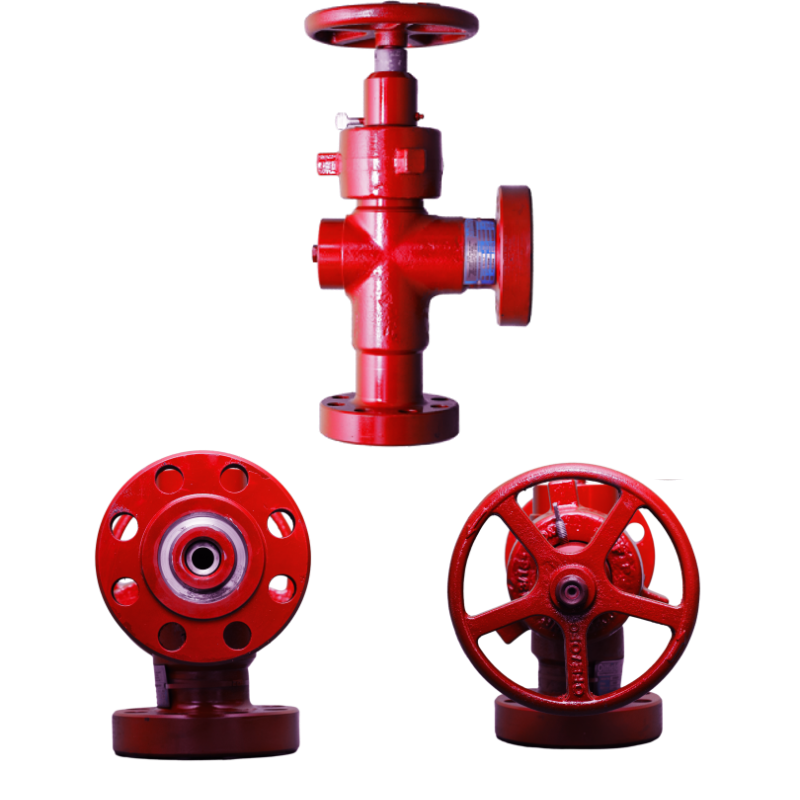

Plug Valves

Specifications:

-

Service Ratings:

-

Standard: 15,000 psi WP / 22,500 psi TP

-

H₂S: 10,000 psi WP / 15,000 psi TP

-

-

Operation Types: Handle / Gear

-

End Connections: 1502 MxF, LP Thread

-

Sizes: 2x2, 3x3

Repair Kit Includes:

-

Plug Seal (x2)

-

Plug (x1)

-

Insert (x2)

-

Insert O-ring (x2)

-

Adjusting Nut O-ring (x1)

Why TYA?

-

API 6A Compliant designs

-

High-performance materials for extended life

-

Precision engineering for consistent flow control

-

Full repair kit availability for reduced downtime

-

Custom sizing available as per customer requirements

-

-

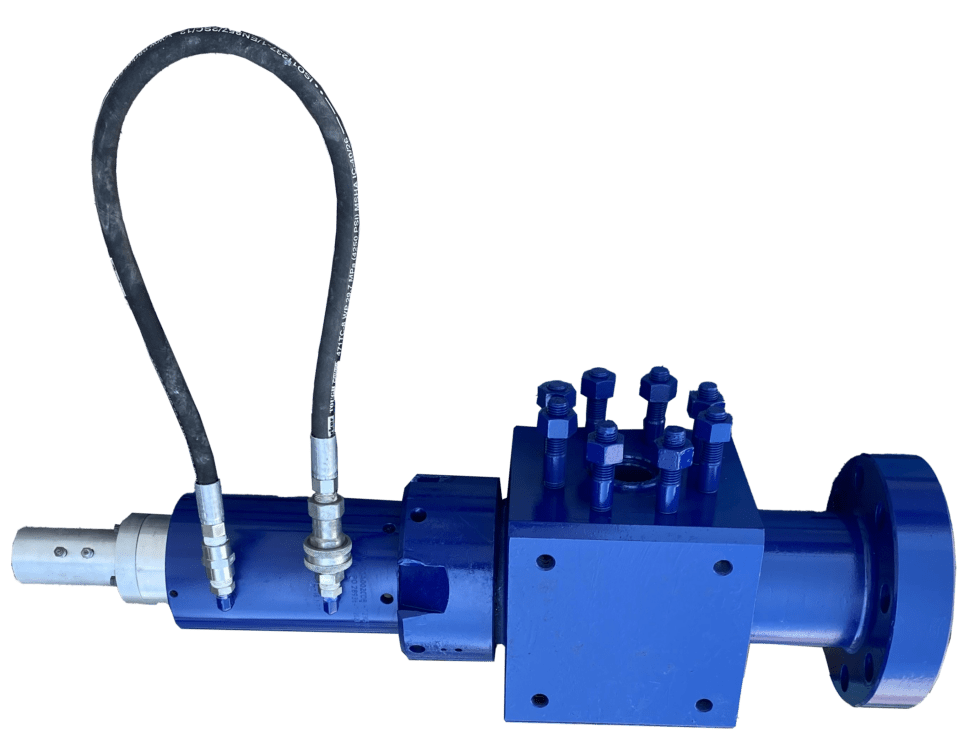

The model CM is an extreme duty hydraulic choke designed with field maintenance in mind.

Features:

- Piston actuator – provides fast movement for pressure manipulation.

- Quick removal actuator.

- 2” trim size, tungsten carbide

- Piston actuator can be modified to a worm gear.

- Reversible gate and seat.

- Solid 2” tungsten carbide gate and seat–patented design provides maximum erosion resistance.

- Pressure balanced gate – reduces operating force.

- Downstream wear sleeve – extended-length solid tungsten carbide seat provides wear protection on the body.

- Large buffer cavity – slows velocity and distributes the impact of solids.

- Bleeder port to relieve pressure from choke body prior to bonnet removal for inspection or maintenance.

- Full-rated working pressure throttling capability.

- Exceeds ANSI Class V drop tight seat seal shut off.

-

The model CM is a extreme duty hydraulic choke designed with field maintenance in mind.

Features:

- Worm gear actuator – provides precise movement for pressure manipulation control; self-locking to prevent movement.

- Quick removal actuator.

- 2” trim size, tungsten carbide.

- Manual override capability - on all worm gear actuators.

- Worm gear actuator can be modified to a piston with limited parts.

- Reversible gate and seat.

- Solid 2” tungsten carbide gate and seat – patented design provides maximum erosion resistance.

- Pressure balanced gate – reduces operating force.

- Downstream wear sleeve – extended-length solid tungsten carbide seat provides wear protection on body.

- Large buffer cavity – slows velocity and distributes impact of solids.

- Bleeder port to relieve pressure from choke body prior to bonnet removal for inspection or maintenance.

- Full rated working pressure throttling capability.

- Exceeds ANSI Class V drop tight seal shut off.

-

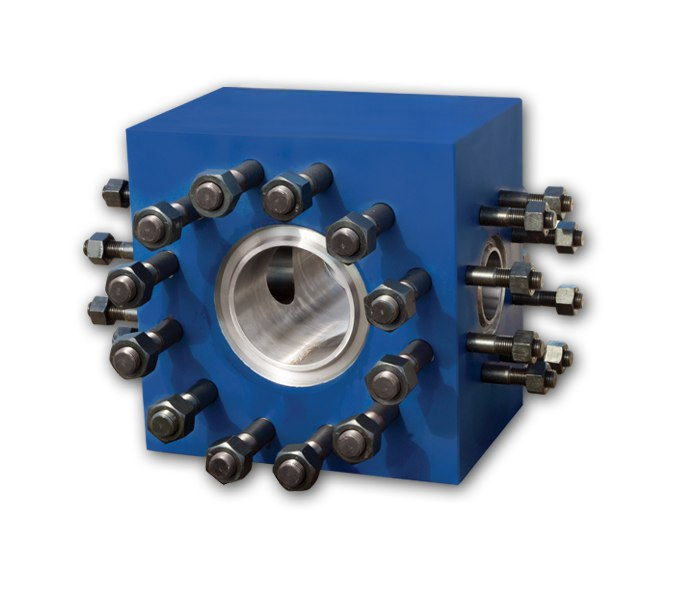

Pressure-containing equipment consisting of flanged or studded connections used to control and direct fluid flow. Crosses and tees are typically a component of frac trees, manifolds, and Christmas/production trees. Can be used in Frac Tree and flowback applications.Flange crosses and tees according to the design requirements and face-to-centerline requirements of API Spec 6A. When specific nominal sizes and combinations of nominal sizes do not appear in API Spec 6A, Studded crosses and tees, flanged crosses and tees are widely used for choke manifolds, kill manifolds, mud manifolds, and Christmas trees. *Various sizes and pressure ratings, custom manufacturing available.

-

Component with studded connections on each end, used to connect flanges with different nominal sizes, pressure ratings and configurations.A Double Studded Adapter (DSA) is commonly used to connect flanges with different nominal sizes, pressure ratings, and configurations. *Various sizes and pressure ratings, custom manufacturing available.