High-Performance Heat Exchanger Manufacturer in India

Our products are built using premium-grade materials and precision manufacturing techniques to ensure maximum heat transfer efficiency, corrosion resistance, and long service life.

We also offer custom heat exchanger design solutions to suit specific process requirements and operational conditions.

Sharma Technocast, we are a leading manufacturer and supplier of industrial heat exchanger in Ahmedabad, India. trusted by clients across air conditioning, refrigeration, power generation, and process industries.

With decades of engineering expertise, we specialize in the design, fabrication, and testing of high-efficiency heat exchangers tailored to meet demanding industrial standards.

Types of Heat Exchanger We Manufacture

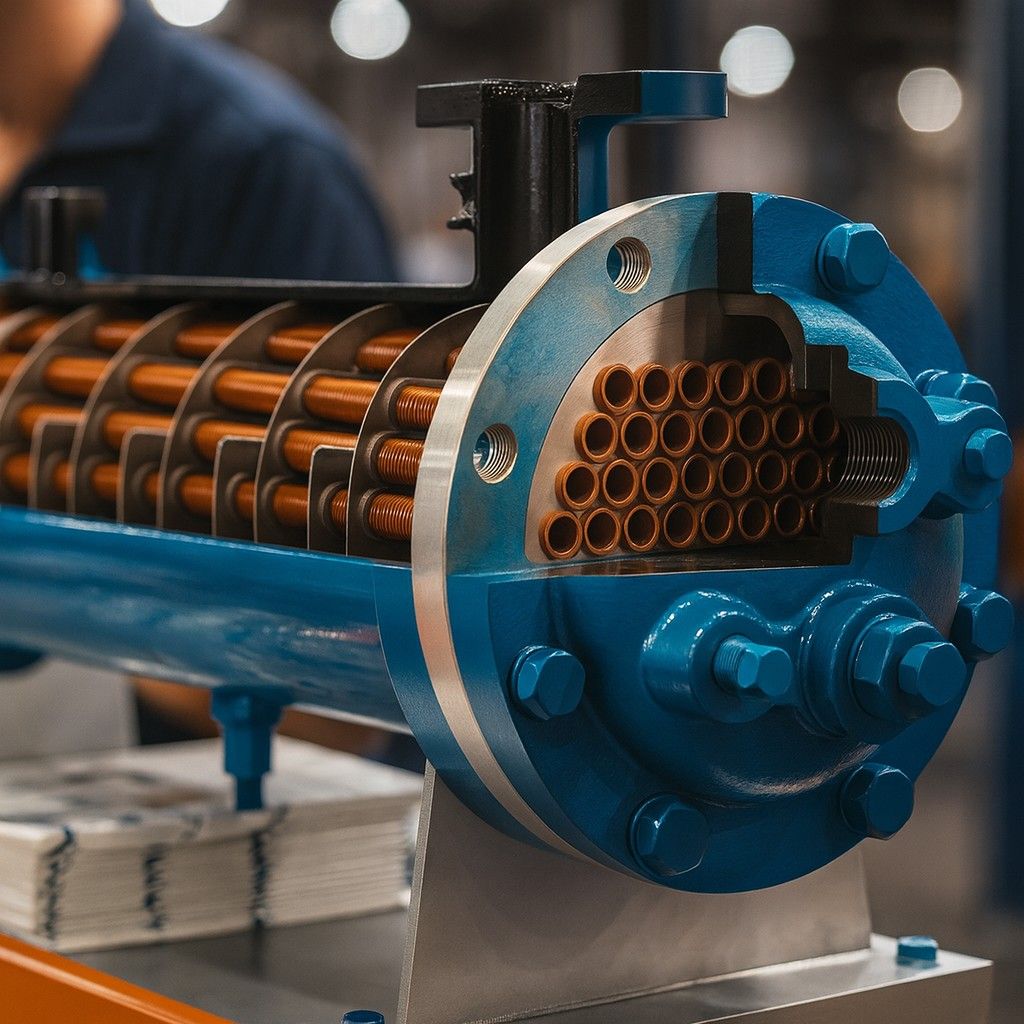

Shell and Tube Heat Exchanger

Also known as tube side medium and shell side medium.

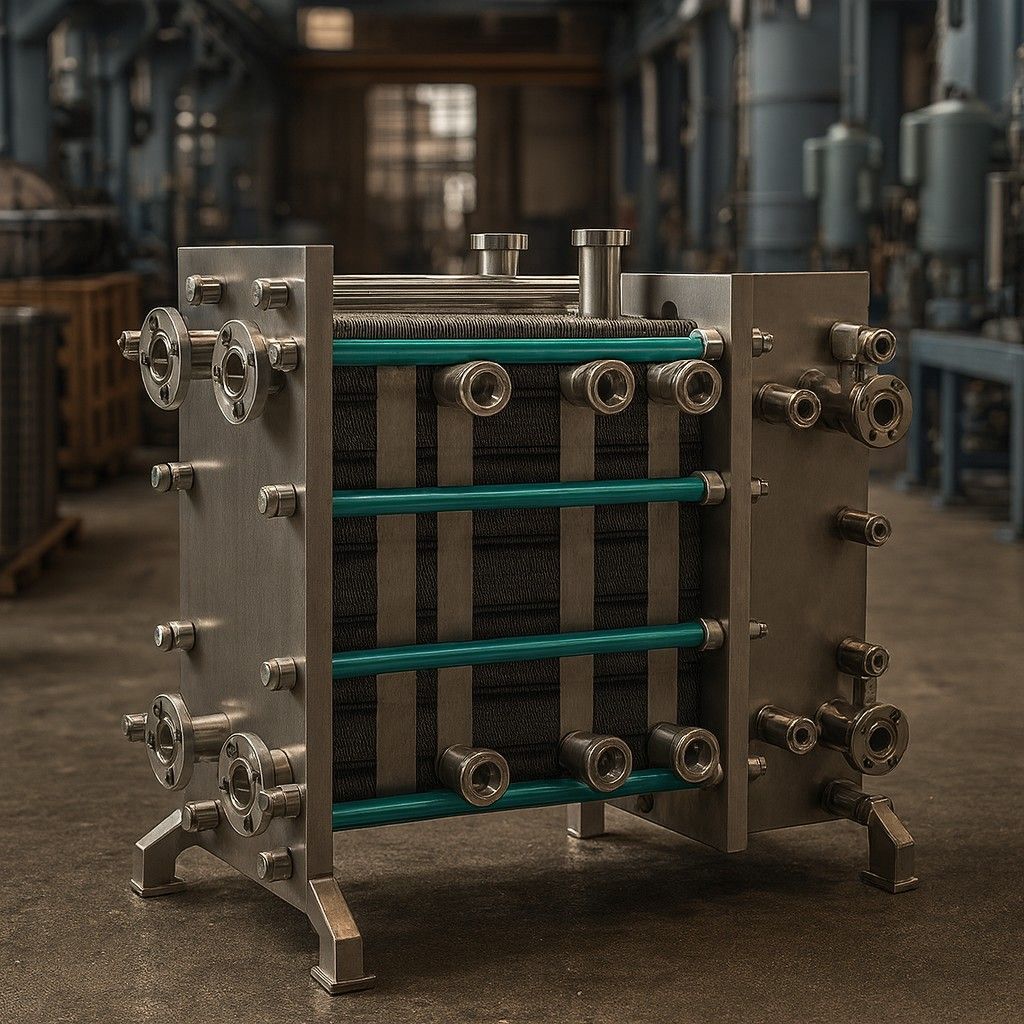

Plate Heat Exchanger

Uses Metal Plates to transfer heat between two fluids.

Request For Quote!

Ready to get started? Contact us today to discuss your project.

Shell and Tube Heat Exchanger

The shell and tube heat exchanger is the most widely used type across process industries.

In this design, the liquid flowing inside the tubes is known as the tube-side fluid, while the one outside is the shell-side fluid. Both have separate inlet and outlet points, ensuring efficient heat transfer without mixing.

At Sharma Technocast, we manufacture high-pressure shell and tube heat exchanger that can handle extreme operating conditions. The tubes act as individual pressure vessels, offering greater strength and cost efficiency compared to large-diameter shells. These units are ideal for chemical, petrochemical, and power generation plants.

Plate Heat Exchanger

Plate heat exchanger are designed for compactness, efficiency, and easy maintenance. They consist of a series of corrugated metal plates that create parallel flow channels for hot and cold fluids.

Our plate exchanger deliver excellent thermal performance, making them suitable for HVAC systems, food processing, and refrigeration industries. They are lightweight, energy-efficient, and customizable to handle various flow rates and temperatures.

Tube Sheet Heat Exchanger

A tube sheet is a critical component in heat exchanger and boilers — a precision-drilled round plate that holds tubes securely and prevents fluid mixing.

our CNC-machined tube sheets are made from high-strength alloys or clad materials to resist corrosion and ensure dimensional accuracy.

Each tube sheet is designed using CAD software for exact hole pattern layout, fluid velocity control, and optimal heat transfer efficiency.

We also manufacture double tube sheets for applications requiring total isolation of fluids — a key safety feature in refineries, chemical plants, and power stations.

professional equipment and a skilled team to meet your specific needs.

Why Choose Sharma Technocast For Heat Exchanger?

- Over two decades of experience in precision fabrication and metal engineering

- In-house testing, inspection, and quality control for every product

- Proven expertise in pressure vessel and process equipment fabrication

- Serving industries across India, the Middle East, and Southeast Asia

- Custom heat exchanger design based on client requirements

Sharma Technocast is your reliable partner for industrial heat exchanger in Ahmedabad and across India, delivering performance-driven, durable, and cost-effective solutions that power your processes efficiently.

Frequently Asked Questions

A heat exchanger works on the principle of heat transfer, where thermal energy moves from a hot fluid to a cold fluid without the two fluids mixing. This is achieved through conduction and convection across metal surfaces or tubes designed to maximize heat flow.

The three major types of heat exchangers are:

- Shell and Tube Heat Exchangers

- Plate Heat Exchangers

- Air-Cooled Heat Exchangers

Each type is used based on temperature, pressure, fluid properties, and industry requirements.

- Stainless Steel (SS304, SS316)

- Carbon Steel

- Copper and Copper Alloys

- Aluminium

- Nickel Alloys, Titanium (for corrosion-resistant applications)

Material selection depends on temperature, corrosion resistance, and fluid compatibility.

HVAC systems use heat exchangers, but HVAC itself is not a heat exchanger.Within HVAC, components like evaporator coils, condenser coils, and heating coils act as heat exchangers to regulate indoor temperature.

The heat exchanger process involves:

- Hot fluid enters the system

- Cold fluid enters separately

- Heat transfers across plates or tubes

- Hot fluid cools, and cold fluid heats up

- Fluids exit through their respective outlets

The entire process is designed for efficient and controlled thermal exchange.

The best heat exchanger depends on your application:

- Plate heat exchangers → Best for high efficiency and compact design

- Shell & tube heat exchangers → Best for high pressure, high temperature, and industrial use

- Air-cooled exchangers → Best where water is limited

Industrial plants commonly prefer Shell & Tube Heat Exchangers for durability and performance.

- Shell or casing

- Tubes or plates

- Tube sheets

- Baffles

- Inlet and outlet nozzles

- End covers or heads

- Gaskets and seals

- Mounting supports

The number of parts may vary depending on the type of exchanger.

You can get high-quality heat exchanger solutions from Sharma Technocast, a trusted manufacturer in Ahmedabad offering shell & tube heat exchangers, plate heat exchangers, condensers, coils, and custom thermal solutions. Our team uses premium-grade materials, precision engineering, and strict quality control to deliver long-lasting, high-performance heat exchangers for industries across India and worldwide.