Trusted Industrial Components and Engineering Parts Manufacturer in India

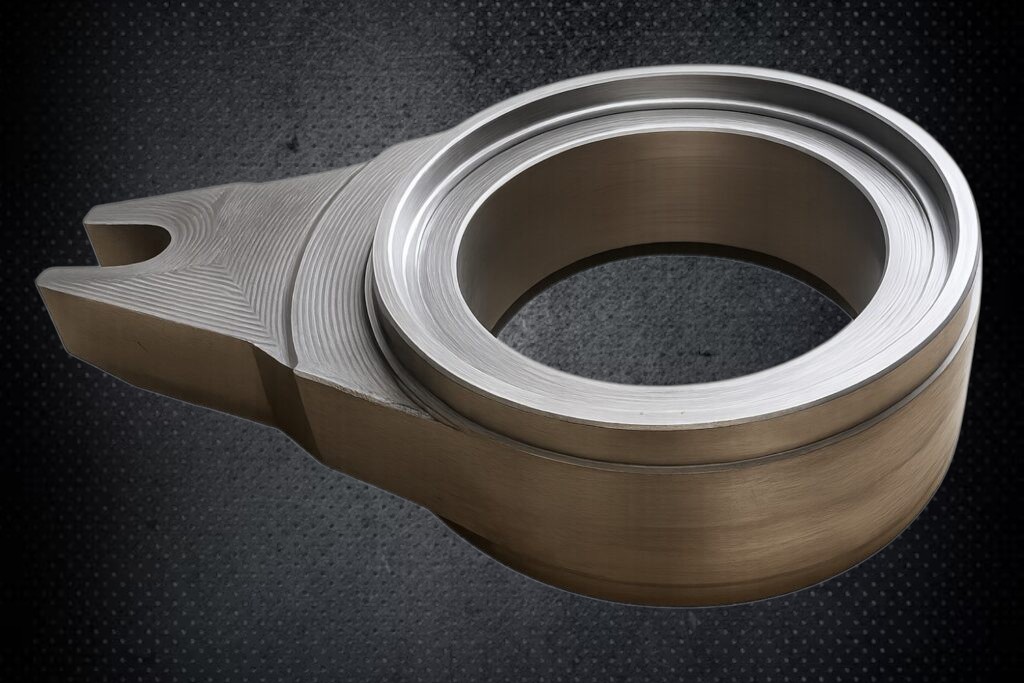

Since 2013, Sharma Technocast has been a leading Engineering Parts & Industrial components Manufacturer in Ahmedabad, Gujarat, India. With well-recognized AS9100 and ISO 9001 certifications, we deliver high-precision, high-performance, and reliable engineering solutions worldwide. We specialize in manufacturing Metal Casting, Forging, Precision Machining, Fabrication, Pipe Bending , Heat Exchangers, Fasteners, Spring Lock Washers, Conveyor Rollers, Tablet Making Machines, and Cotter Pins.

With advanced manufacturing facilities, strict quality control processes, and industry-focused engineering, we supply durable and reliable components for aerospace , automotive, machinery, refineries, oil & gas, Pharmaceuticals , construction, fabrication units, chemical plants, heavy industries, and equipment manufacturers.

Our commitment to accuracy, strength, and long-life performance makes Sharma Technocast one of the top engineering component manufacturers in India, trusted for consistent quality and on-time delivery.

Innovative Solutions for Every Engineering Challenge

Proven Project Experience

Our Work Philosophy

Engagement

Coordination

Quality Assurance

Transparency

Our Recent Blogs

Understanding Sheet Metal Fabrication: Techniques, Tools & Applications

How Accurate Is Precision Machining? Tolerance Levels Explained

Watch Sharma Technocast Process Videos

Frequently Asked Questions

We manufacture precision-machined parts, metal casting parts, forging parts, fabrication components, fasteners, cotter pins, and washers for multiple industries

Yes, we produce fully customized parts based on your CAD drawing, step file, technical specifications, or physical sample, ensuring accurate tolerances.

Send your requirement here: https://www.sharmatechnocast.com/contact/

We supply engineering parts to automotive, industrial machinery, construction, electrical, oil & gas, agriculture, aerospace , refineries , pharma , power and general engineering industries.

View industries we serve: https://www.sharmatechnocast.com/industries-we-serve/

Our facility uses CMM inspection, hardness testing, surface roughness checks, dimensional checks and full documentation to ensure defect-free components.

We work with carbon steel, stainless steel, aluminum, brass, alloy steel, cast iron, ductile iron, and high-performance alloys depending on application needs.

Yes, we deliver all machined components, casting components, forging components, and fasteners worldwide with safe and reliable logistics support.

You can share your drawing or requirement, and we usually provide a detailed quotation within 24–48 hours.

Request a quote: https://www.sharmatechnocast.com/contact/

We handle both small and large production runs. From prototype samples to bulk manufacturing, our facility supports flexible order quantities based on customer requirements.

Yes, Sharma Technocast provides end-to-end engineering solutions, including machining, casting, forging, and fabrication, ensuring faster delivery and consistent quality.

You can reach us through our contact form, email, or phone. Our technical team will help you review your requirements and suggest the best manufacturing solution.

Get in touch: https://www.sharmatechnocast.com/contact/

Stay in the Know